Freeze-drying is a critical step in solventless extraction.

When done correctly, freeze-drying will ensure stability in your bubble hash. Residual moisture can lead to microbial issues, while increased drying temperatures can lead to reduced terpene content and darker colours.

With that being said, small changes in freeze-drying settings can improve rosin yields and quality. The right equipment and process can make a huge difference in the quality of your bubble hash, and the time it takes to complete a drying cycle.

If you want to bypass the trial and error and fast-track your freeze drying process to perfection, our expert consulting is here to help you achieve optimal results and efficiency.

Keep on reading to learn how to optimize freeze-drying procedures.

What is Freeze-Drying?

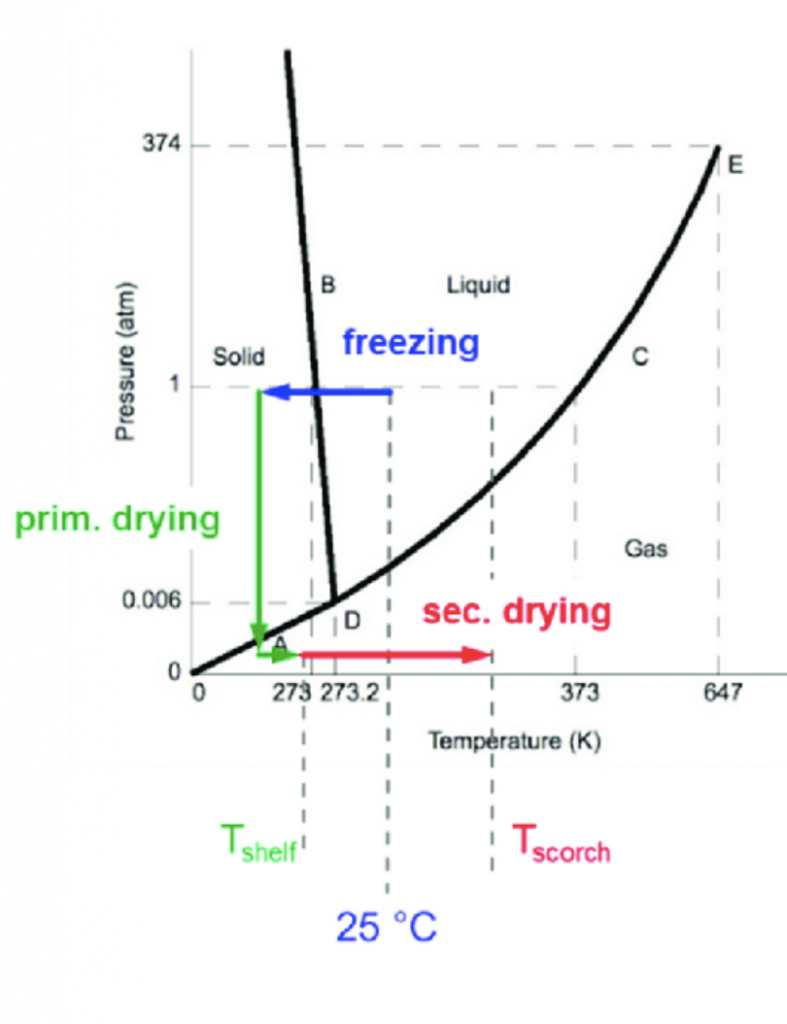

Freeze-drying is the process of lyophilization. In other words, pressure and energy are used to dry a product.

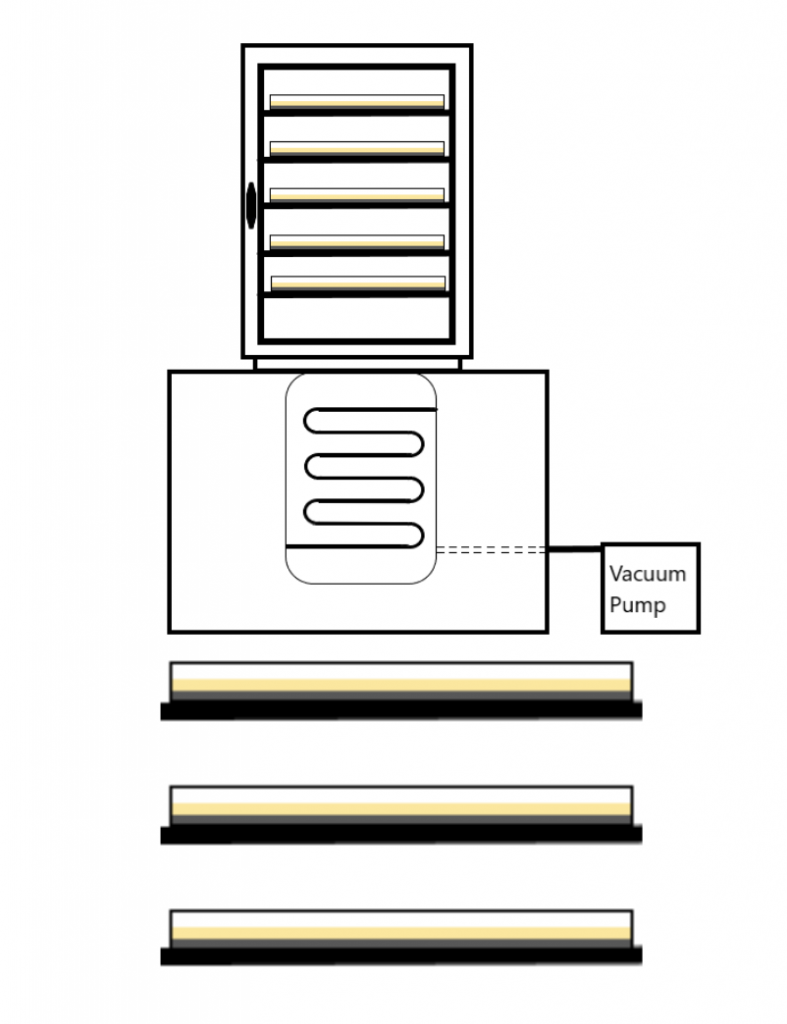

To begin the freeze-drying process, a sample is frozen (on trays for our purposes). Then, it is placed in a chamber with heated shelves. A vacuum is then pulled to reduce pressure in the chamber, while energy is applied in the form of heat. This enables the process of sublimation to occur.

Now, the water which has been frozen to a solid can be turned into vapour, and then evacuated from the bubble hash and water slurry.

How Does Freeze-Drying Work?

Freeze-drying works from the top, down.

As vapour escapes from the product, it condenses and refreezes in the condenser. This is why crystal formation, water content, and patty thickness are all crucial factors in the freeze-drying process.

As the cake layer moves its way down the frozen material, it becomes increasingly difficult for water vapour to escape the product and move to the condenser.

Larger crystal formations will create pathways in the cake for water vapor to escape as the ice is sublimated out of the product.

Higher water content will decrease the density of the cake as it forms, since there are less solids concentrated in the mixture.

With that being said, it is important to find the balance between too much and too little water. Both scenarios can extend dry times, but it is safer to err on the side of too much water.

Tray Preparation

Tray preparation is the first step in optimizing freeze-drying procedures.

Even flat trays, with the correct water to hash ratio, are essential to a successful lyophilization cycle.

When collecting hash from bubble bags, try to maintain the consistency of wet cake batter. The goal is to create an even layer of wet bubble hash on the tray.

This can be accomplished by tapping your tray on a table or cart while collecting. If the hash does not spread easily, it likely requires a little more water.

Freezing Bubble Hash

Freezing is a critical step, and must not be overlooked.

Some freeze dryers feature active cooling. These freeze dryers will undergo a freeze-cycle prior to the initiation of the drying program.

Ideally, bubble hash should be frozen to -40C/F, prior to beginning the freeze-drying process. It is not recommended to use a freezer colder than this, as the rate of freezing will be too fast. As a result, it can limit the size of crystal growth.

Freeze Dryer Selection

Finally, equipment selection is important when deciding what your hash drying goals are.

If you want ultimate control of your drying process, then you will need to select a freeze dryer designed for commercial use.

Selecting a freeze dryer that allows custom recipe creation allows processors to dry bubble hash faster, and with better results. This also provides more control over the appearance and moisture content of your final product.

Commercial systems are also likely to use better components, so they will be more reliable. Freeze dryers designed for home use are not meant to be run every day.

Similarly, freeze dryers specified for home use do not allow full programming. As a result, you are unable to achieve a recipe specific to hash drying. This tends to result in extensive dry cycles, with less control over residual moisture content.

Whistler Technologies is proud to consistently be at the forefront of solventless extraction technology.

For that reason, we are the first cannabis extraction company to partner with LabConco. With LabConco, we develop recipes specific to freeze drying bubble hash.

We continue to develop our network of capable freeze-drying equipment, by working with freeze dryer manufacturers to examine and test new systems.

Reach out today, to find out what solutions we can offer to optimize your hash drying procedures. And, don’ forget to check out our freeze-drying webinar for more tips and tricks!